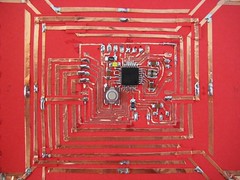

Using a vinyl cutter to cut the traces of a circuit design out of copper foil with adhesive backing. The copper traces can then be transferred to a base to make a flexible circuit. Additionally a solder mask can be lasercut (or also vinylcut) from fabric with adhesive backing and applied to isolate the traces and only expose the copper where one needs access to solder the components.

Step-by-Step

The circuit used in this example was designed in Eagle by Nathalie Krueger of the Design Research Lab at UdK Berlin.

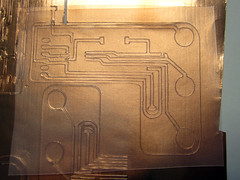

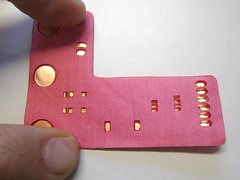

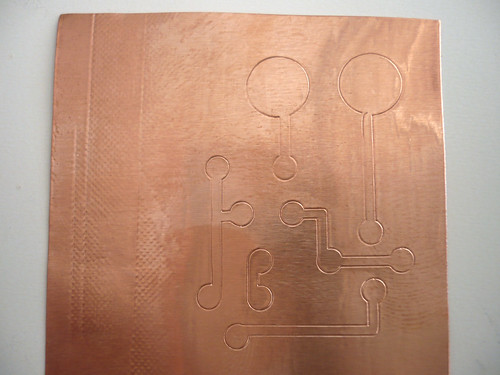

Prepare your vector graphics files. One for cutting the traces of the circuit from copper tape. Another for cutting your solder-mask from fabric or tape with adhesive or iron-on backing. If you designed your circuit in Eagle you can export an image, open it in Illustrator, trace and expand the image to create vectors for cutting. Black = circuit traces. Orange = solder mask.

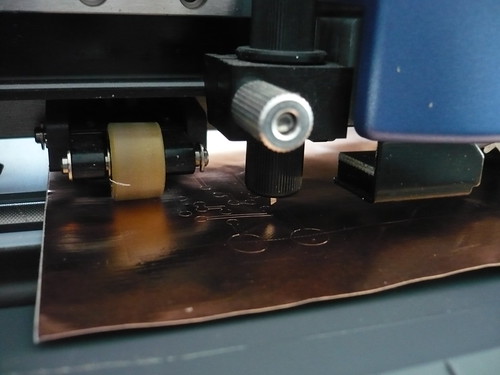

This circuit was cut on a Graphtec CE6000-60 viny cutter using the Graphtec’s Cutting Master 3 Illustrator plug-in.

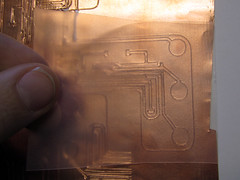

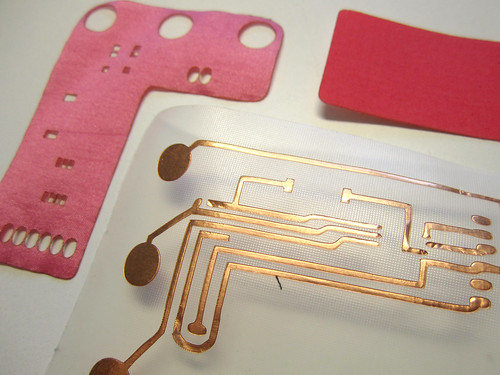

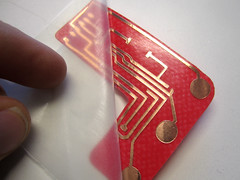

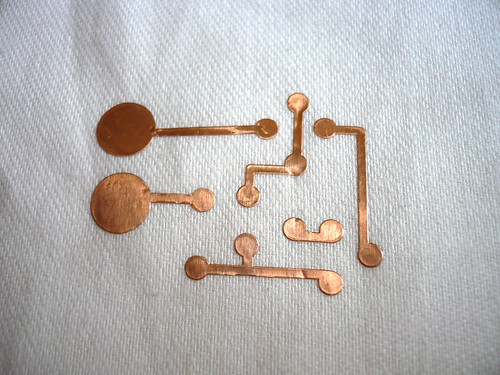

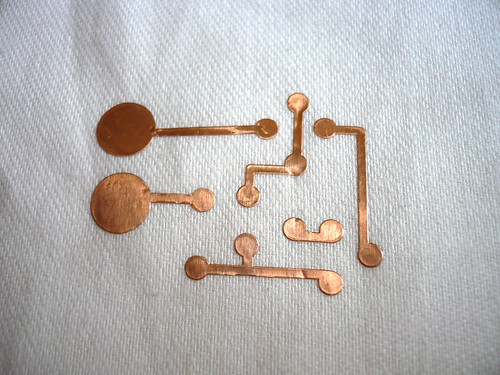

Remove all the copper that is NOT part of your circuit. You can do this either before or after transfering the copper to some sticky (but not too sticky) tape.

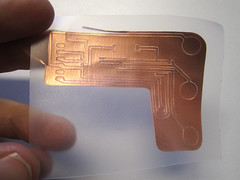

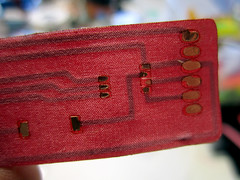

Transfer the copper traces of the circuit to a base medium of your choice. Think about picking a material or fabric that will not melt or burn under the heat of soldering on the components.

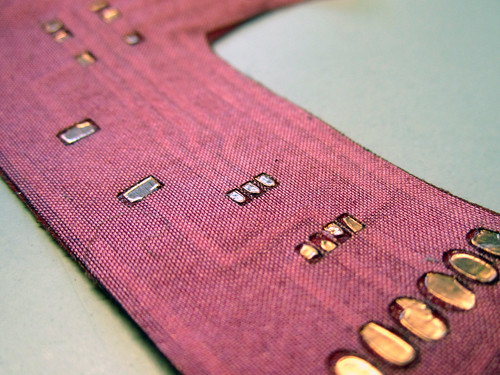

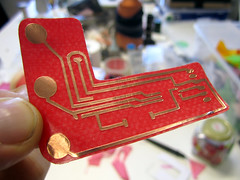

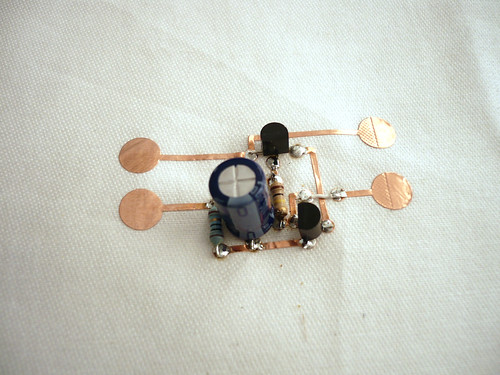

Your transferred circuit should look something like this.

Solder any breaks before fusing solder mask.

Fuse solder mask.

Mika’s Review

Using a Roland CAMM 1 GX-24E vinyl cutter and Cutronic Foil from TechSoft to make a simple multi-vibrator circuit following this schematic.

Cutting went straight forward. I used Pen Force as 80 gf and speed is set to 1cm/s (lowest). The result is very clean.

Pealing off the unwanted copper foil was easier than I thought. Occasionally I had to use pen knife to support the separation, overall it is cut very cleanly. Then I sticked a wide piece of masking tape from front side to transfer the foil from its backing and still keep it in place. Then stick it to a backing fabric (I used white cotton non-stretchy fabric) and press the copper bits so it sticks to it good.

Soldering components on this copper foil is very easy. It sticks to solder very well, and connection seems strong enough. (we can do some washing test later). At the end, I’ve pierced popper through copper foil and fabric to make a connection to other parts, and it seems to work well as a connector.

References

>> Jie’s Vinylcut Fabduino

Jie Qi’s I/O paper >> http://fab.cba.mit.edu/classes/MIT/863.10/people/jie.qi/jieweek14.html

Jie’s Flickr set >> http://www.flickr.com/photos/jieq/sets/72157625670797923/

Ed Baafi’s Fabduino >> http://fab.cba.mit.edu/classes/MIT/863.10/people/Edward.Baafi/assignment5.html

>> Simon’s Instruction

Great post by Simon de Bakker on FashioningTech

http://www.v2.nl/lab/blog/cutout-circuit-board

>> Nadya’s Instruction

Instructable by Nadya Peek on vinyl cutting copper foil circuits

http://www.instructables.com/id/How_to_make_circuits_with_a_Roland_CAMM_mign_cutte/

>> Hannah’s Vinylcut Tilt Sensor

Supplies

Cutronic Foil for PCBs >> http://www.techsoft.co.uk/products/materials/knife-cutting/cutronic-foil-pcbs.asp

3M 1126 Copper Foil with Conductive Adhesive Tape >> http://solutions.3m.com/wps/portal/3M/en_US/3MElectrical/Home/ProductsServices/Products/?PC_7_RJH9U5230GE3E02LECIE20OES1_nid=781VJDMC6Lbe870G8G819Fgl

>> http://search.digikey.com/scripts/dksearch/dksus.dll?pname&WT.z_cid=ref_octopart_dkc_buynow&site=us&lang=en&name=3M1126D-ND

3M #1126 copper tape with conductive adhesive 6”x 36 yds @$225.18/roll from Budnick Converting >> http://www.budnickconverting.com

[…] http://www.kobakant.at/DIY/?p=1132 >> http://www.v2.nl/lab/blog/cutout-circuit-board >> […]

Thanks for that awesome write-up! Bookmarked and dugg!

[…] I like the simple stuff though I think: […]