Designs with Reuse in Mind

It happened for the second time now that a solution for an e-textile connection/integration lead me to want to design a “textile component” that has equivalent standing to reusable textile parts such as buttons, clasps, rings… generally hard elements that are not damaged in the process of adding/integrating them into the textile and are also removable without damaging them.

Criteria that make something re-usable:

– Processes of adding and removing do not damage the item

– The item has a generic use

– The item is worth re-using because of cost, emotional attachment, resource efficiency

Again, coming back to our practice at KOBA over the last months, here some observations of where we ran into the idea of designing a part of a project that it could be re-used.

Breakout Boards

Often for “embedding” hard electronics into soft textile materials we end up designing and producing some kind of “breakout board” on which the connections of smaller components are “broken out” to larger, sewable connections. Creating a transition between fully hard and fully soft. What if we were to design a set of generic breakout boards for the components we use most often (ATtiny microcontrollers, transistors/MOSFETS, LEDs…). Then we could produce these in “bulk” and take care that their designs are resource efficient. And they would also be re-usable….

BUT! Do we really want to do this? Are we not killing the bespoke-ness of this way of making technology by always thinking about how to make everything efficient? From our experience now of having designed and made all kinds of breakout boards, I would plea for the benefit of designing certain parts of the circuit to be re-moveable (and thus maybe also re-usable) but instead of pre-making generic breakouts, we should master techniques for producing these using different materials/techniques/aesthetics.

The alternative to creating breakout boards would be to integrate the components more directly, but this is often less desirable because the base fabric of the garment might be extremely light, soft, stretchy and one needs to create a more robust base for these parts and the transition from fully hard to fully soft.

The following are some examples from KOBA projects where we have created part of the circuit as a self-contained element that can be (ideally) easily removed and reused.

“ohne mich” Control Circuit

This is basically a felt circuitbaord that breaks out two ATtiny pins via transistors.

EMF Amplifier “Buttons”

>> http://www.kobakant.at/DIY/?p=7092

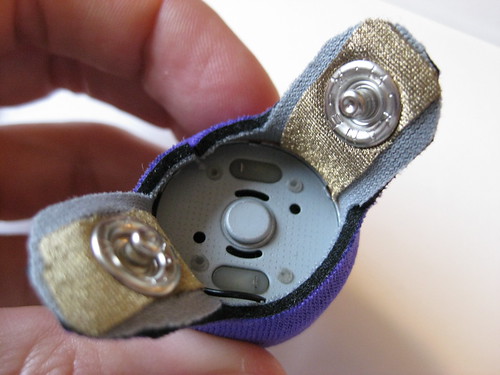

Rachel’s JumpNorth Motor Boards

Inspired by earlier work >> http://www.kobakant.at/DIY/?p=45

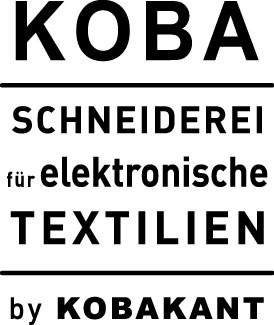

Bumblebee Breakout

>> http://www.kobakant.at/DIY/?p=7166

ATtiny Breakout

This was a test that did not get used in the final piece because it seemed unnecessary to create a breakout for reasons of robustness or aesthetics.

NON-Breakout Examples

To contrast the above examples, here are examples where the components are connected more directly into the project and removing them would require desoldering of leads which can also count as “removable”, but to some extent less reusable because the desoldering process can damage the parts. But of course the absence of additional breakout material means less material(s) are used. But those used may be less re-usable.

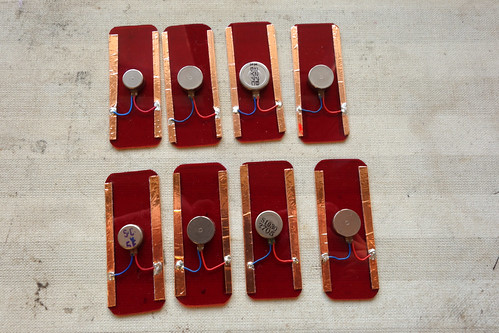

ATtiny soldered directly to the conductive threads:

SMD LEDs for soldering directly to conductive thread:

Conclusion

To end with a concluding question: Does making something more reusable necessary entail using more materials to make the reusable design???