Lulu Monitor: May

This post summarizes the developments we’ve made on the Lulu project during May 2018. The WORTH funding we received to help fund this work requires that we submit monthly reports, so our developments are documented as responses to their Monthly Monitor questions.

To keep up with our developments, please follow us:

On Flickr >> https://www.flickr.com/photos/plusea/albums/72157691569545895

On YouTube >> https://youtu.be/HRloIkJaIwE

On Twitter >> https://twitter.com/hashtag/lulu

1. Provide an updated status of the degree of compliance with the expected objectives.

What stage have you reached?

We have now begun the design stage of our Lulu development which involves defining our constraints and sourcing the materials we will need to build with.

What outcomes have you reached?

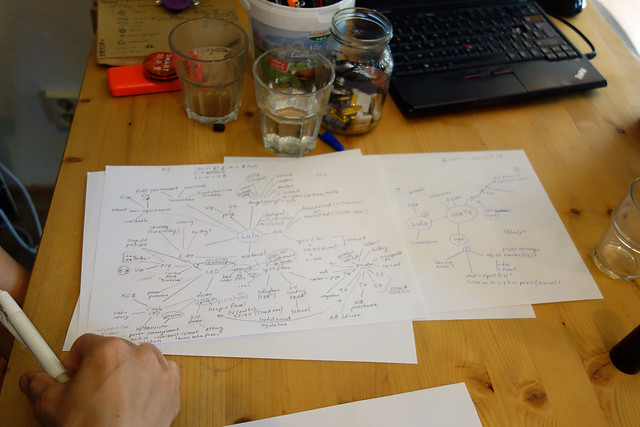

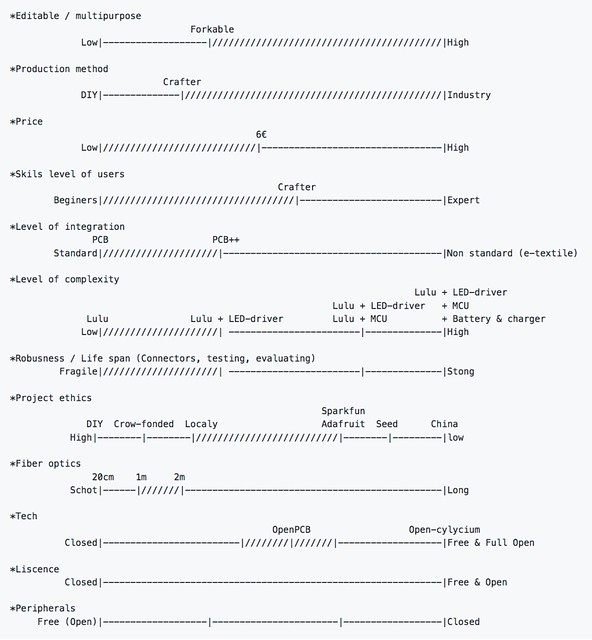

We have defined our constraints (see IMG bellow), delegated out tasks to individuals in the team (see Gantt chart bellow) and we have set ourselves a next immediate deadline of finalizing the a first test PCB design by the end of June 2018.

Our constraints visualized as sliding scales between two extremes:

Our Gantt chart depicting our working time-line for the next 6-9 months:

2. What are the key activities you have completed during the last month?

Meeting in Berlin

We all met in Berlin this month to work our our design considerations and plan for the next 6-9 months.

Discussion

We spent 1 1/2 days discussing our motivations for wanting to develop the Lulu so as to help us come up wit relevant constraints. These include:

what do we mean by “manufacturable design”? fully industrial or still some use of hand-assembly?

–> first design iteration (end June) should explore form, materials and implementation as well as building up the community around the technology.

–> second design iteration (end summer) should begin to look into industrial/automated manufacturability as it relates to bringing down costs while still living up to our standards of ethical and environmental production.

who are our target audience?

–> textile craftspeople, e-textilers, wearable technologists, DIY/maker and students in these fields.

how much can they afford? how much can the Lulu cost?

–> ideally 2 Euro/piece, maximum 6 Euro/piece

where do we want to be at the end of the WORTH funding cycle?

–> have a tested design and community around it

–> contact to a manufacturer and distributor combination

Name

We discussed the name of the project. “Lulu” comes from Lucette, a girls name which means “light” in french.

Versions

We are currently thinking to have two Lulu designs:

Lulu Star – e-textile + LED + driver + optic-fiber

Lulu Daisy(chain) – e-textile + neopixel + optic-fiber (has built-in driver)

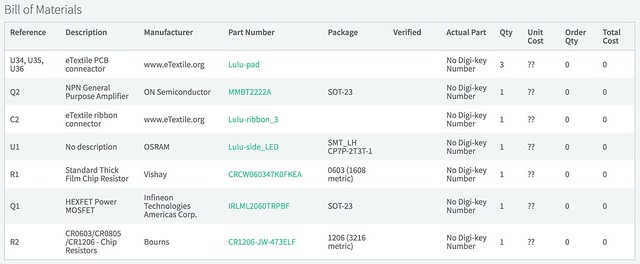

PCB Design

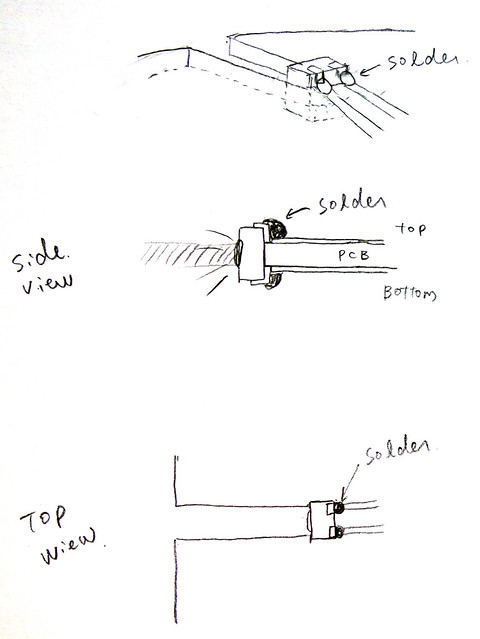

We plan to mount the LED on the side of the PCB like this:

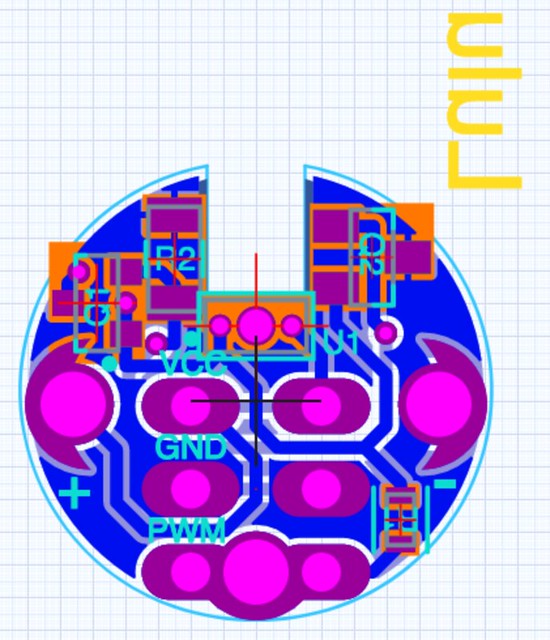

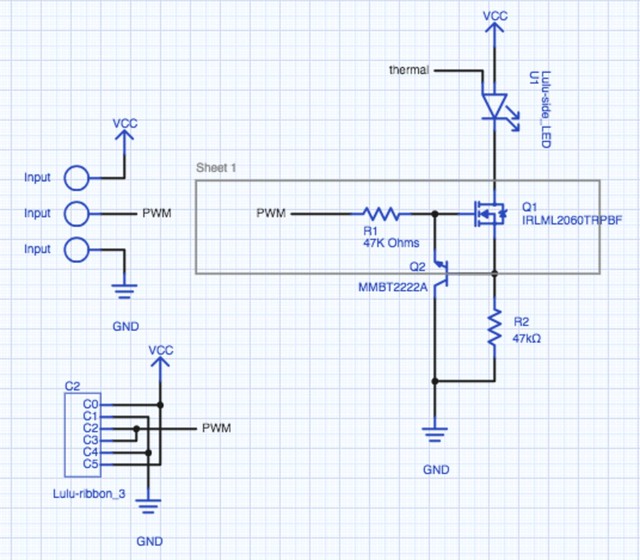

Maurin began work on the first Lulu PCB iteration with SMF flat-mount LED mounted on the side of thet PCB:

First designs >> https://upverter.com/DataPaulette/5193c940bede1099/Lulu-star/

PCB Shape:

The boards could be shape that tessellates, like an Escher drawing or a triangle….

PCB Manufacturer

We met with a PCB manufacturer in Berlin (http://andus.de/) to discuss the possibility of industrially (pick-and-place) assembling the LED mounted on the side of the PCB. They told us they would speak with their pick-and-place person, but have not gotten back to us since.

Mentor Meet

We had our first Skype session with our project mentor Ricardo N. He offered to help us research and contact possible distributors (who might also have their own manufacturing facilities – or not).

3. Have you encountered any problem during the last month? If so, please list them below along with the respective countermeasures.

PCB manufacturer in Berlin (http://andus.de/) told us they would speak with their pick-and-place person, but have not gotten back to us since.

4. What results do you want to achieve over the next month?

Next month our main goal is to finalize the first iteration (roughly 100pcs) of the Lulu Star/Daisy and to find a manufacturer to produce these with.

The following month (August 2018) we plan to distribute some of these boards in the e-textile community during the following events/workshops in order to illicit feedback from people using the design.

E-Textile Summercamp

>> http://etextile-summercamp.org/

KOBA School of Wicked Fabrics

>> http://www.kobakant.at/KOBA/koba-school-of-wickedfabrics/

PIFcamp

>> http://pif.camp/

5. How is your project applying the insights and advice of the mentoring programme you are being coached on?

We have not yet received any relevant insights or advice from the mentoring programme. We hope that in the next months WORTH will provide us with input about:

– Certificates (CE, ISO, RoHS???)

– Licensing, Legal stuff