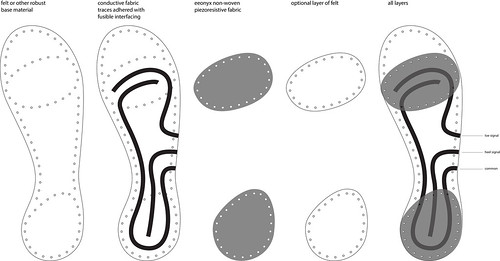

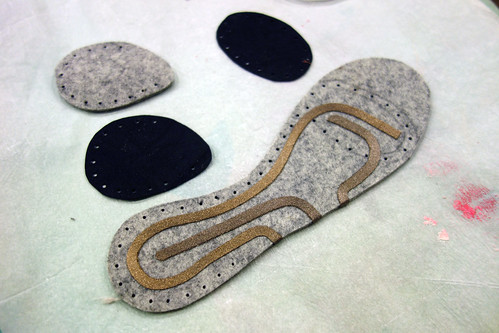

These Sonic Insoles demonstrate a simple way of adding pressure sensors in your shoes. Fusing strips of conductive fabric to the surface of a robust base material such as felt. Cutting shapes of piezoresistive fabric for the pressure sensitive areas. Punching holes for sewing and using thick thread to hold everything together.

Fusing Curved Conductive Traces

Stretch conductive fabric is prepared with a fusible interface backing (iron-on glue) and then cut into straight strips. When ironing-on these strips to the base felt one can maneuver them while they are hot to create curved lines. No need to cut out curved shapes, which would cause a waste of fabric.

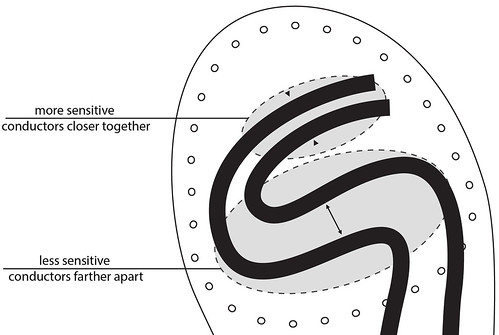

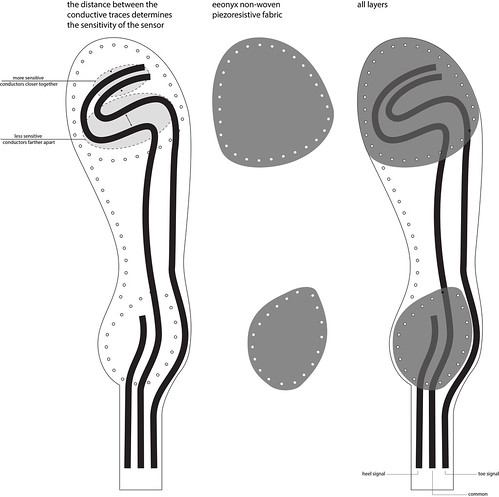

Pressure Sensitivity

The conductive traces come close together in the sensitive areas where shapes of piezoresistive Eeonyx non-woven fabric laid over these traces. The closer together the traces are, the more sensitive this area will be to pressure – meaning less pressure will cause a greater decrease in resistance.

Punching Holes

With a hole punch holes are punched at 1cm intervals, then a needle with some thick (non-conductive!) thread can be used to sew the shapes in place. The punching of the holes it not necessary, but makes it easier to neatly sew through the thick felt. Also these stitches can be easily undone and edited without damaging the fabric.

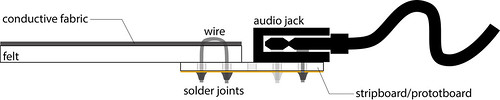

Construction

Magic Shoes

During PIFcamp 2017, Vaclav from Bastl Instruments made himself a custom pair of these insoles for his “Magic Shoes”, and included two nice design implementations:

1) Sensor Design

In the front toe area his design lays the traces such that they are further apart under the ball of the foot and closer together under the toes. This allows him to control the range of one pressure sensor with two different inputs. Pressure from the ball of the foot brings the resistance of the sensor down to a certain level, and then additional pressure from the toes brings the resistance down even further.

2) Hard/Soft Connections

To connect to the jack sockets mounted on a piece of protoboard he poked wires through the strips of conductive fabric and felt, and soldered them to the protoboard. The heat of the soldering melted the stretch conductive fabric and burns the conductive layer of silver, but if the soldering is done quickly at a low temperature I think this style of hard/soft connection is a very nice solution!

wire to conductive fabric connection >> http://www.kobakant.at/DIY/?p=6928

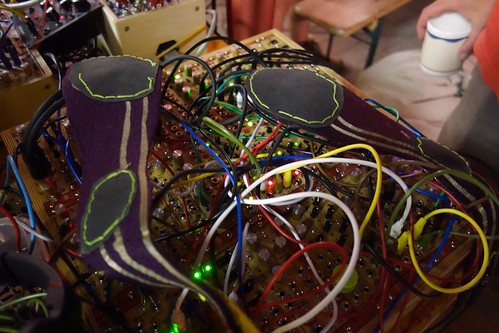

Making Music

Vaclav writes about how he uses the variable resistance from these sensors in his synthesizer set:

“The resistive pressure pads from the shoes were connected to the Sense module. The module converts the resistance into voltage and further amplifies and offsets to obtain the highest usable range from the sensor. Further the module uses comparator to set threshold for the pressure and outputs a gate signal when the pressure surpasses the threshold. There were 4 Sense modules in total – 2 pressure pads per shoe. Mostly i used these thresholds to mute different parts and events in my performance, but i also used the continuous pressure voltage to open and close filter on the bassline.”

Video by Batt Girl:

Leave a comment